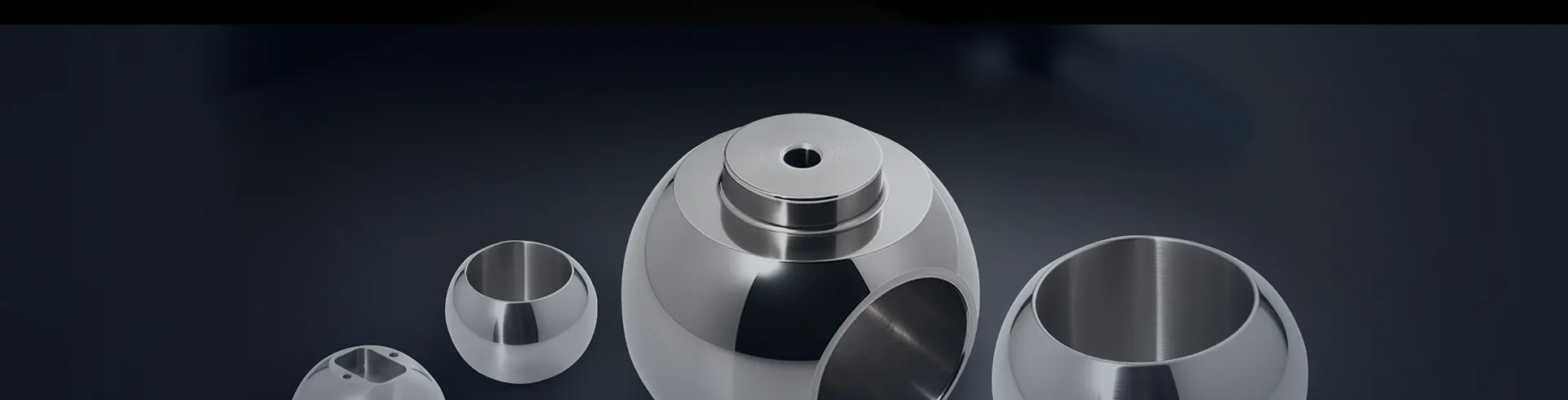

TongBall Zirconium Oxide-Coated Valve Balls are engineered to withstand extreme high-temperature oxidizing environments and corrosion from specific molten media. The CoO or Co₃O₄-based coating, applied via plasma spraying, boasts a dense structure retaining excellent oxidation and thermal shock resistance at temperatures up to 1000°C. It exhibits good chemical inertness to certain molten salts, metals, and alkaline conditions. Ideal for high-temperature valves in specialty metallurgy, glass manufacturing, and advanced energy systems, it provides reliable protection to extend the service life of critical components.