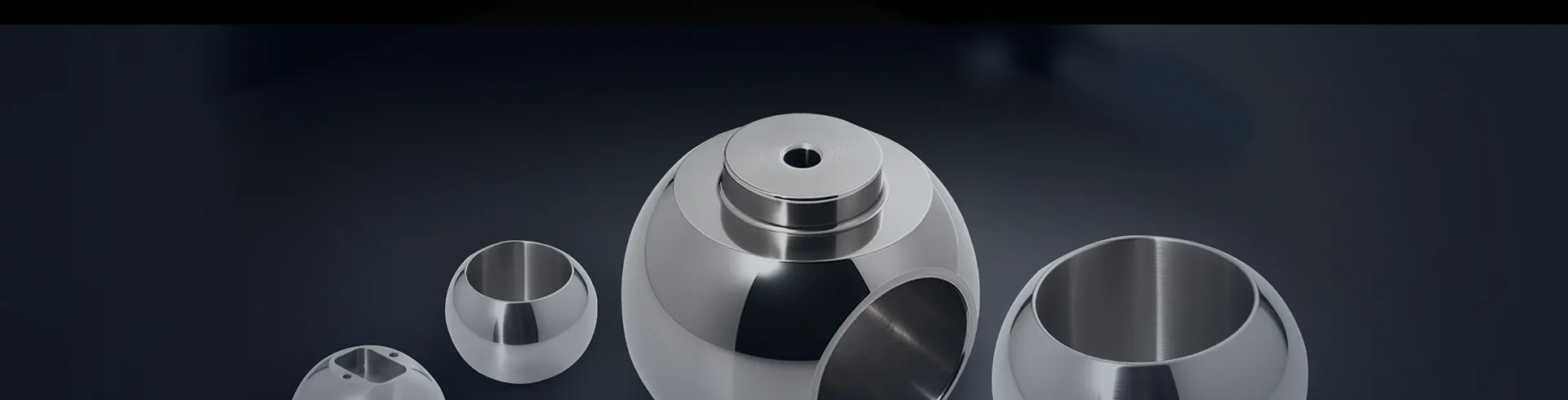

TongBall Chromium Oxide-Coated Valve Balls offer a high-performance solution for combined high-temperature corrosion and wear conditions. The Cr₂O₃ coating, applied via high-velocity flame or plasma spraying, delivers high hardness (HV 1100-1400), low porosity, excellent chemical corrosion resistance, and stable high-temperature performance. It effectively resists acid, alkali, and corrosive gas attack while offering strong abrasive wear resistance. Widely utilized in valves for chemical, pulp & paper, and flue gas treatment industries facing combined severe corrosion and solid particle erosion, it significantly enhances operational reliability and cost-effectiveness.