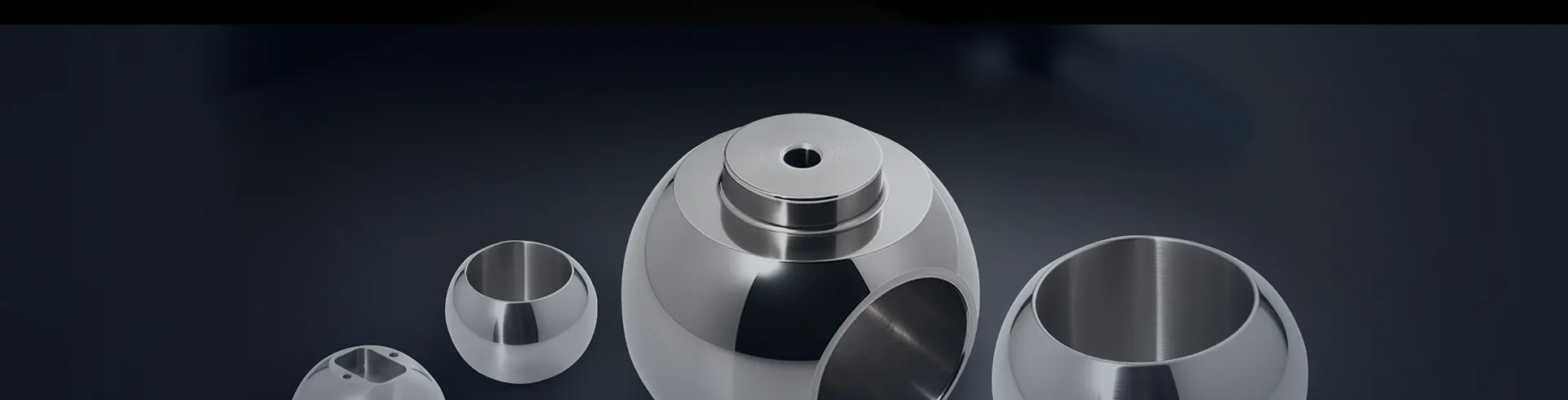

TongBall Stainless Steel Valve Stem offer a full range of austenitic (304/316), martensitic (420/440C) and precipitation-hardening (17-4PH) material solutions.Through precision cold drawing or CNC turning forming, the dimensional accuracy is controlled within ±0.01mm, and the straightness is less than 0.02mm/m. The surface can be treated with mechanical polishing, electrolytic polishing or hard chromium coating, and the Ra value can be below 0.2μm.

Covering ISO 5211, DIN standard and non-standard interface, the working temperature covers -196°C to 450°C, widely used in the chemical, pharmaceutical, food and shipbuilding industries of corrosive media and sanitary conditions, taking into consideration the corrosion resistance, wear resistance and assembly interchangeability.