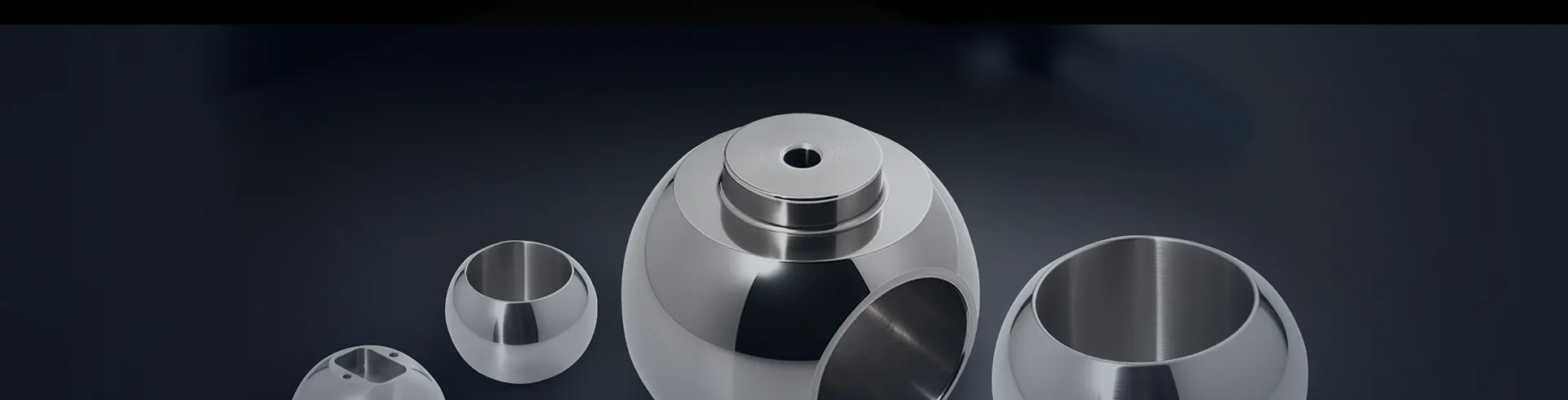

TongBall Titanium Oxide Coated Valve Balls is engineered for highly corrosive and erosive environments. Formed via high-velocity plasma spraying, the dense Rutile-phase TiO₂ coating achieves a hardness exceeding HRA 85 and provides outstanding corrosion resistance. It maintains stable performance in concentrated acids, alkalis, and electrochemical media, making it an ideal alternative to special stainless steels in demanding applications such as chlor-alkali processing and hydrometallurgy where both corrosion and solid particle wear are prevalent.