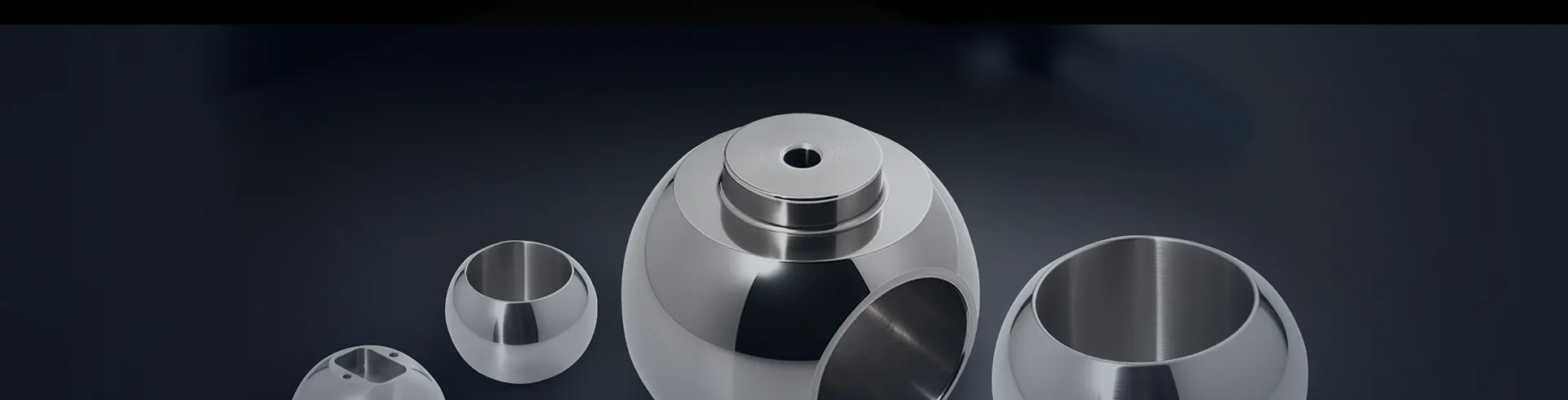

TongBall chromium carbide sprayed valve balls are specially designed to cope with the superimposed working conditions of high-temperature wear and corrosion. Through the supersonic flame spraying process, a dense coating mainly composed of Cr3C2-NiCr , with a surface hardness of HRC 70-75, maintaining excellent performance below 540°C. Its unique advantage lies in the resistance to abrasive wear and high temperature oxidation/vulcanization corrosion at the same time. It is the ideal choice for smoke dust removal, high temperature valves and wear-resistant rings, and its life is far beyond that of conventional hardened steel balls.