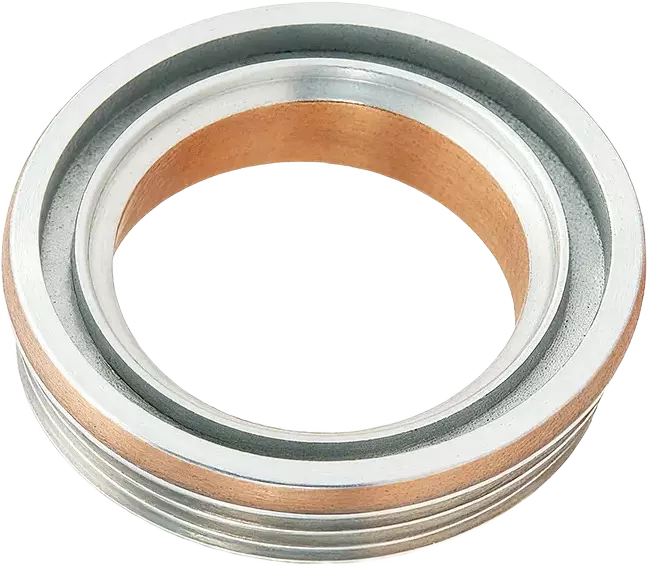

As a professional manufacturer, TongBall's soft-sealed valve seats are based on precision injection molding, compression sintering and CNC machining processes, achieving a dimensional accuracy of ±0.05mm and a sealing surface finish of Ra less than 0.4μm. Product support embedded metal frame with elastic structure integration, and through strict factory sealed and endurance test.

This series of valve seats are suitable for working conditions ranging from -200°C to 260°C, and comply with standards such as FDA, USP Class VI and TA-Luft. They are widely used in fields such as chemical engineering, pharmaceuticals, food, semiconductors and cryogenic systems, meeting the requirements of cleanliness, corrosion resistance and long-life sealing.