- Home

- About us

- Case Show

-

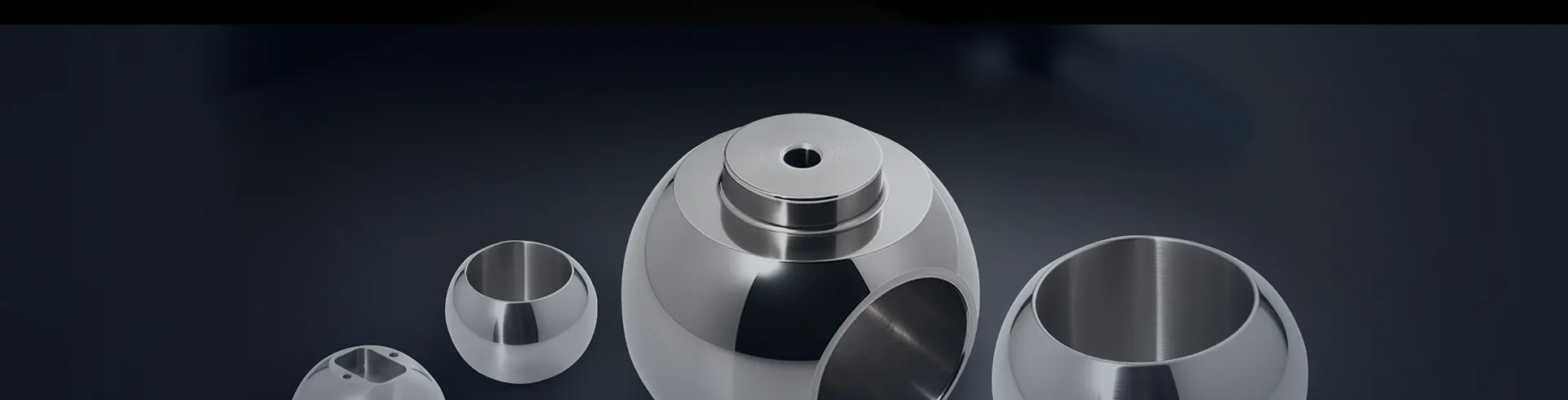

Valve Components

Valve BallsV-type Valve Balls Eccentric Semi-Balls T-type Valve Balls L-type Valve Balls Four-way Valve Balls Trunnion Valve Balls Floating Valve Balls Nickel-plated Valve Balls Stainless Steel Valve Balls Duplex Steel Valve Balls Inconel Alloy Valve Balls Incoloy Alloy Valve Balls Hastelloy Alloy Valve Balls Monel Alloy Valve Balls Ceramic Valve Balls Titanium Valve Balls Zirconium Valve Balls Tantalum Valve Balls Custom Valve Balls

- Production Control

-

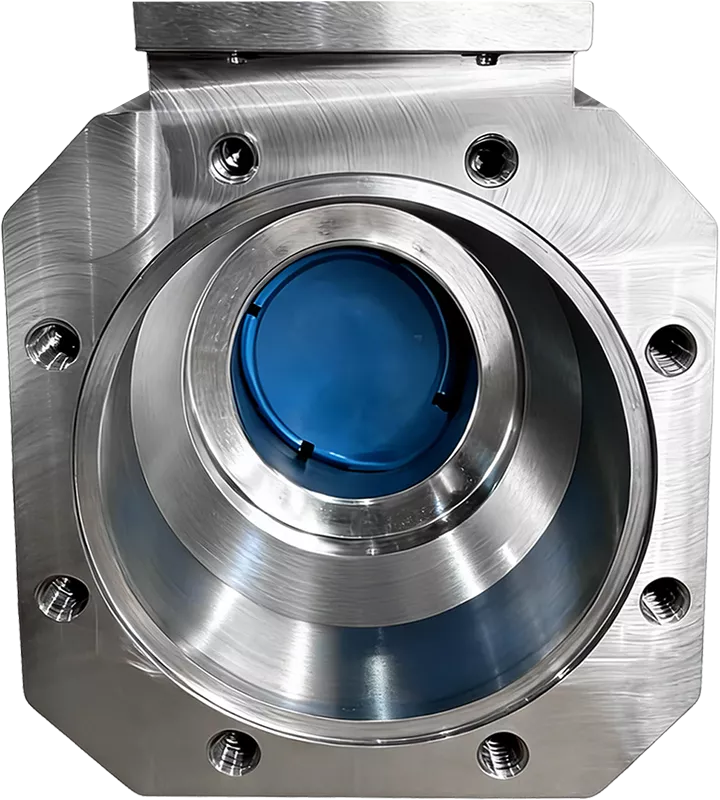

Quality Control

-

News

-

Contact us