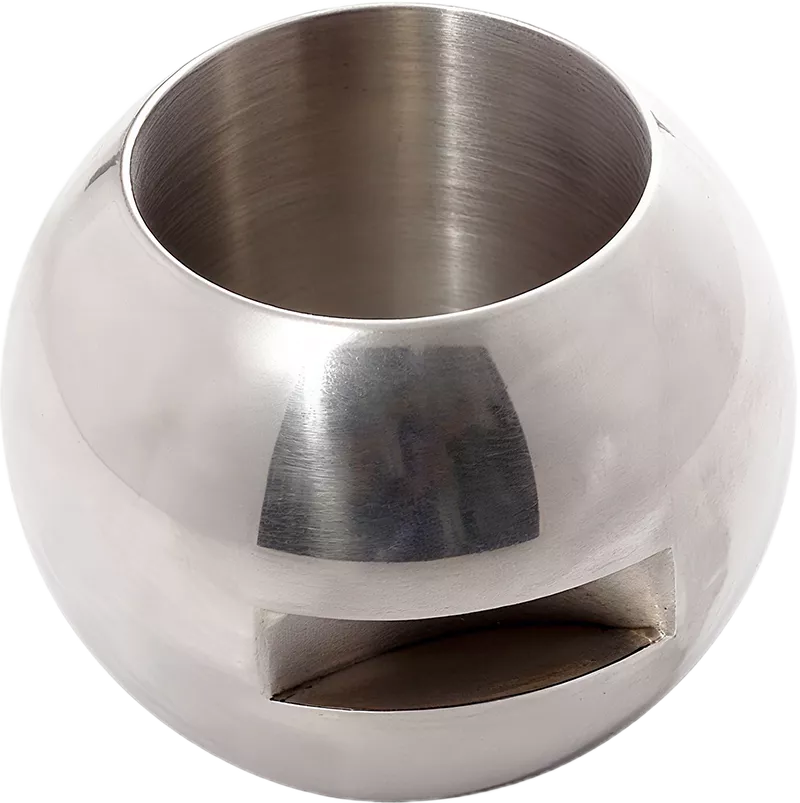

TongBall's zirconia ceramic-coated valve balls leverage the phase transformation toughening of ZrO₂ and advanced thermal spray technology. The partially stabilized zirconia coating formed by plasma spraying exhibits exceptional thermal shock resistance, high toughness, and low thermal conductivity. With strong chemical inertness, it delivers outstanding resistance to corrosive wear in high-temperature (up to 1100°C) and strongly acidic or alkaline media, making it ideal for demanding applications requiring both wear resistance and prevention of media adhesion.