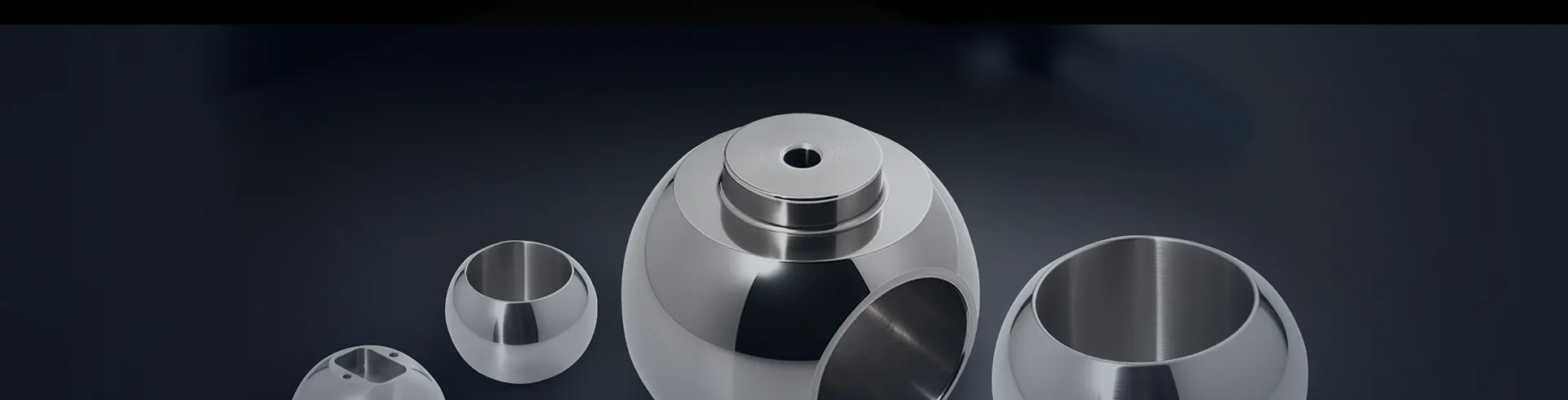

TongBall Titanium Nitride-Coated Valve Balls are manufactured using Physical Vapor Deposition (PVD) or reactive plasma spraying, forming a dense TiN coating. Featuring a distinctive gold hue, the coating achieves a surface hardness exceeding HV 2000 and an extremely low friction coefficient (<0.2), delivering exceptional wear resistance and good chemical stability. It significantly enhances the anti-galling and anti-wear performance of the ball under frequent cycling while helping lower valve operating torque. This makes it an ideal surface enhancement solution for high-precision control valves and general industrial valves requiring long service life and low maintenance.