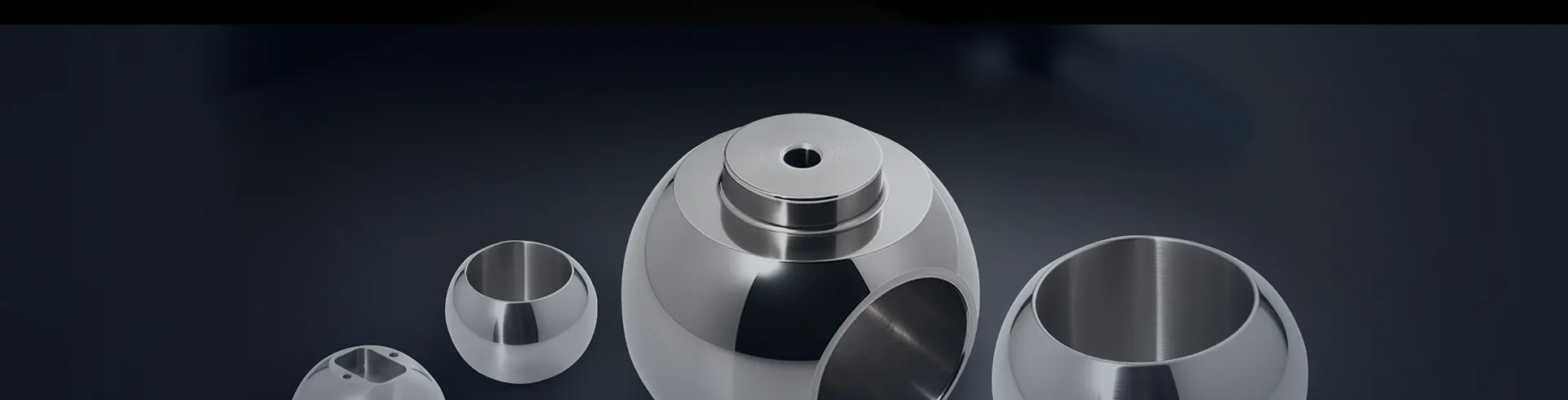

TongBall Metal Seated Valve Seats specially designed for a soft seal condition of zero leakage requirement.Using Stellite alloy (Stellite 6/21), carbide or supersonic spraying tungsten carbide/chromium carbide surface, the working surface hardness can reach HRC 60-70, and the valve ball is matched to achieve line sealing contact.Precision machining ensures that the flatness is ≤0.001mm, and pressure adaptive compensation can be achieved through disc springs or elastic gaskets. It is suitable for high-temperature (up to 800°C), high-pressure, solid particle-containing and highly corrosive media, meeting the API 6D fire resistance test and anti-seizing requirements. It is a key component for harsh working conditions in the oil and gas, coal chemical and nuclear power industries.