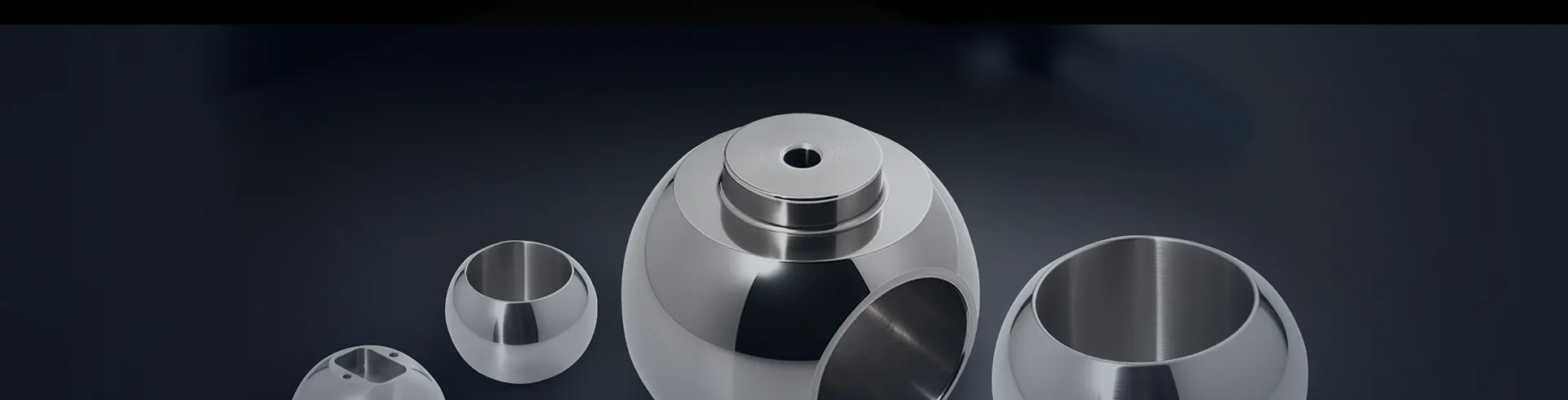

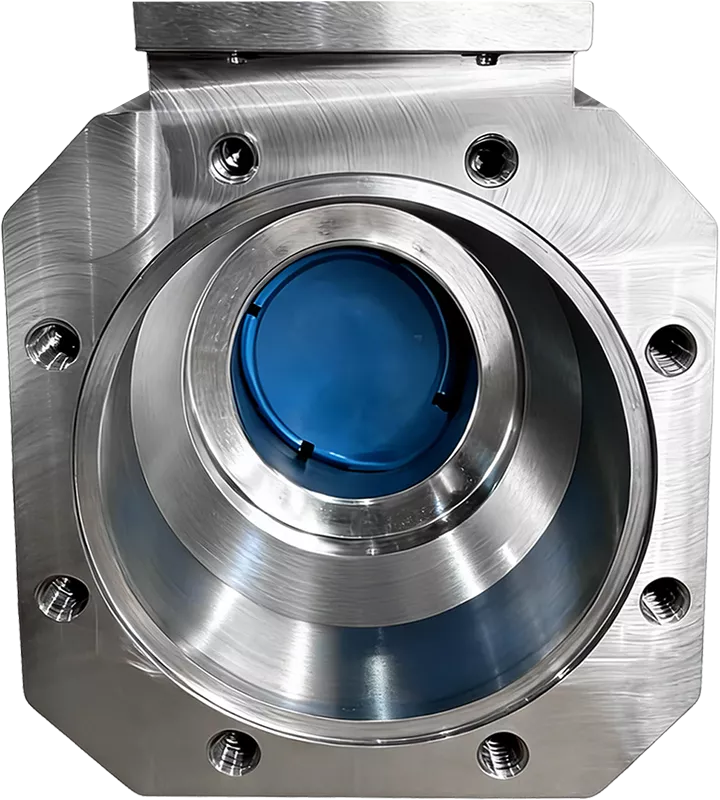

TongBall's Tungsten carbide-coated valve seats are manufactured using the same HVOF process as our valve balls, ensuring perfect compatibility and synergistic wear resistance for the sealing pair. The WC-Co or WC-Co-Cr coating delivers ultra-high bond strength (≥80 MPa) and extremely low porosity (<1%), with surface hardness exceeding HV1300. Specifically designed to withstand impact and shear wear from highly abrasive media such as coal slurry, mineral slurry, and catalysts, these seats form an extended-life sealing system when paired with their corresponding valve balls. This synergy can extend the overall valve overhaul interval multiple times, significantly improving equipment operational efficiency and cost-effectiveness.