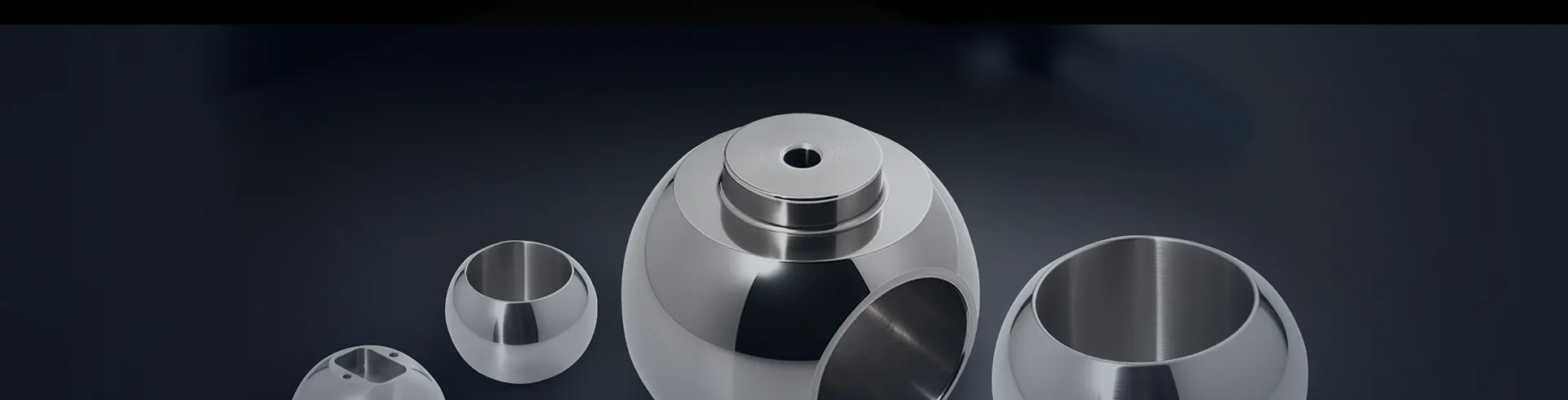

TongBall’s tungsten carbide-coated valve balls, produced via HVOF (High-Velocity Oxygen Fuel) spraying, set the standard for wear resistance in extreme abrasion environments. The WC-Co or WC-Co-Cr coating exhibits high bond strength, porosity below 1%, and microhardness exceeding HV1300. Designed specifically for media such as coal slurry, mineral slurry, and heavy residual oil, these balls deliver unparalleled protection under intense erosive conditions, extending replacement intervals by 3–5 times and significantly reducing maintenance costs.