YONGJIA TONG BALL VALVE CO., LTD. recently sent a delegation of technical specialists to participate in the 28th International Thermal Spray Symposium (ITSS 2025) and the 29th China National Thermal Spray Conference (CNTSC 2025), held in Chengdu. The company's attendance was aimed at enhancing its technical capabilities in valve ball surface treatment and establishing a solid foundation for future product performance upgrades.

During the conference, the team focused particularly on the latest applications of thermal spraying technology in valve manufacturing. Through exchanges with other authoritative institutions, they gained deep insights into recent advancements in rotating plasma spray technology. Notably, domestic rotating plasma spray gun technology has achieved significant breakthroughs, now capable of spraying minimum apertures of 40 mm, with maximum working current of 550 A, power usage of 35 kW, and maximum spray depth of 1000 mm—multiple performance indicators that have reached internationally advanced levels.

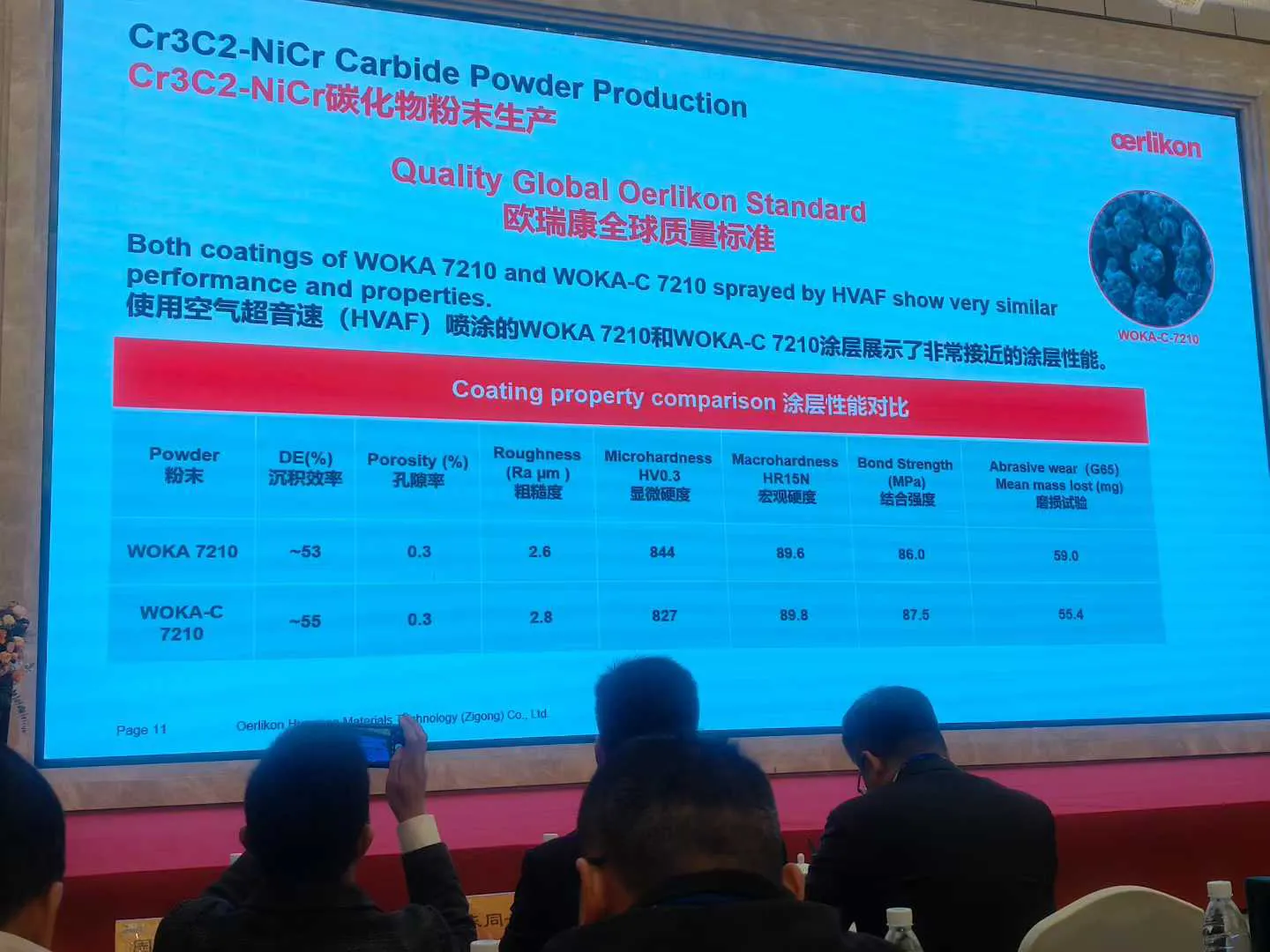

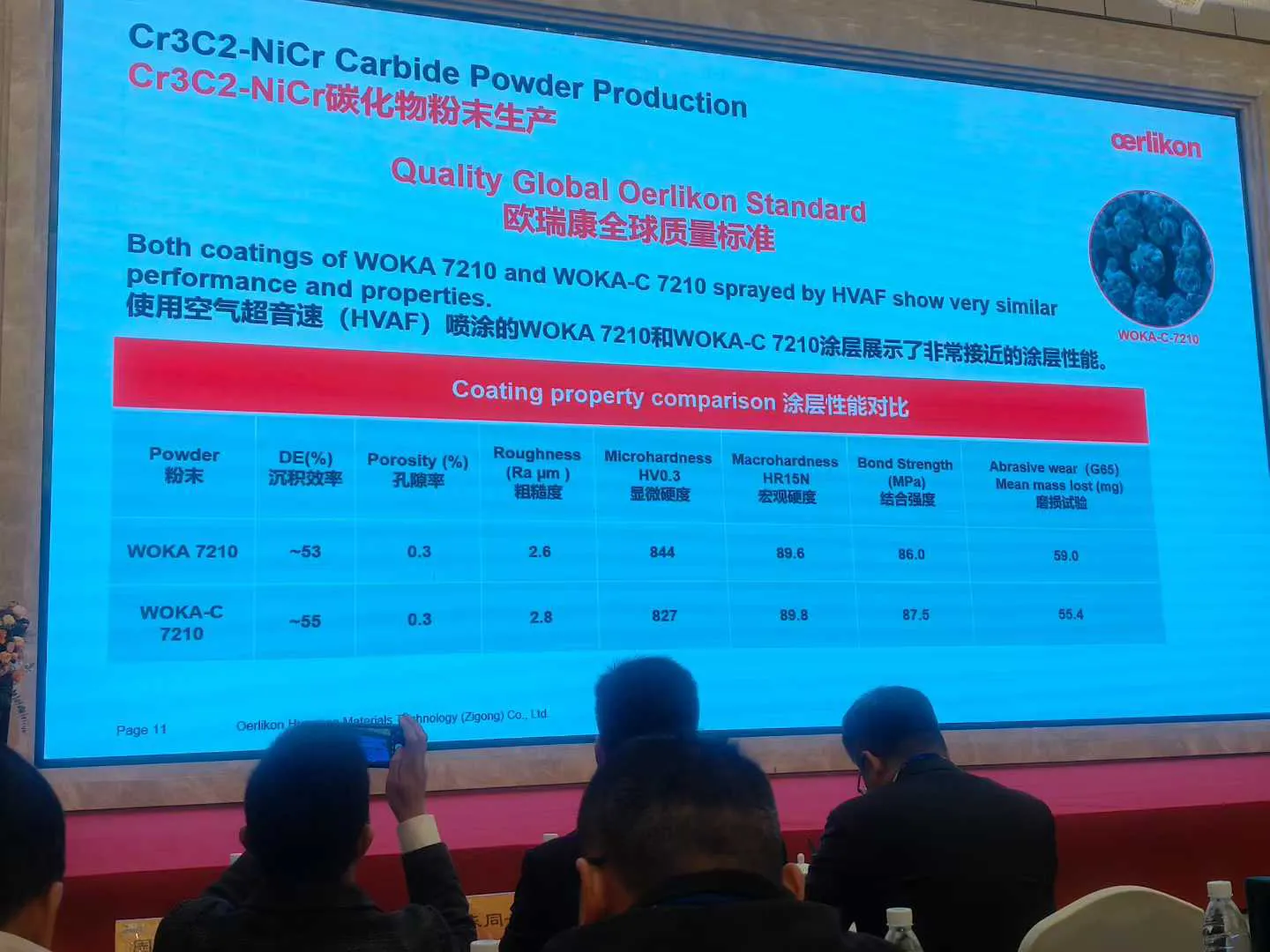

Through these systematic technical exchanges, the company's team has developed a more profound understanding of the application of High-Velocity Air Fuel (HVAF) and plasma spraying technologies in valve manufacturing. YONGJIA TONG BALL VALVE CO., LTD. is committed to actively promoting the innovative application of these advanced technologies on the surface of ball valve components. By improving the wear resistance and corrosion resistance of key parts, the company will provide customers with more competitive, high-quality valve products.